MEKSMART

GENERAL NEWS

Author: Meker Meksmart

Update: 23/07/2025

DIFFICULTIES IN INVENTORY CONTROL, WHAT IS THE SOLUTION FOR ENTERPRISES TO MANAGE PHARMACEUTICAL WAREHOUSES EFFECTIVELY?

Pharmaceutical products are characterized by large quantities, diverse types, production batches, expiry dates, suppliers, etc. Some pharmaceuticals require special storage conditions in terms of temperature, humidity, and light. Therefore, inventory monitoring and control pose many challenges for pharmaceutical businesses. What solutions help businesses manage pharmaceutical warehouses effectively?

Inventory control is a key factor in effective pharmaceutical warehouse management, ensuring business operations and sustainable development of the business. Good and strict inventory control helps avoid expired or damaged pharmaceutical products, ensuring quality and safety for users. Good inventory control helps avoid excess or shortage of products, minimizing storage costs and costs of destroying expired pharmaceutical products.

Large quantities make it difficult to control pharmaceutical inventories

Common difficulties in controlling pharmaceutical inventories

1. Managing the shelf life of pharmaceutical products

The pharmaceutical industry is characterized by products with an expiry date. However, the large amount of data, large quantity of goods, diversity in types, production batches, suppliers, etc. make it difficult to monitor and control the expiry date of each batch. The risk of expired drugs causes waste and affects the health of consumers.

2. Inaccurate inventory

Large quantities of products, diverse in content, units, etc. make it difficult to manage pharmaceutical warehouses. Manual inventory is prone to errors, information loss and needs to be done regularly, consuming warehouse inventory personnel. Not being able to grasp the actual inventory quantity, making it difficult to forecast market demand, can easily lead to shortages or surpluses of goods, causing loss of costs for businesses.

3. Difficulties in the import - export management process

The import - export process in pharmaceutical warehouse management is complicated, requiring high accuracy. Difficulties in tracking and recording import - export information, storing documents, retrieving shipment history, etc. Loose management of import - export of pharmaceutical warehouses, causing the risk of loss of goods, affecting the reputation of the business.

4. Difficulties in optimizing warehouse space

Limited warehouse space while the number of pharmaceutical products is large, with diverse packaging specifications and packaging shapes, making it difficult to arrange goods scientifically. Goods are piled up, making it difficult to search and inventory. Storage conditions are not guaranteed, which can affect the quality and shelf life of drugs.

Difficulties in optimizing pharmaceutical warehouse space

5. Difficulties in complying with industry regulations and standards

The pharmaceutical industry has many strict regulations and standards. Difficulty in ensuring compliance with regulations on drug preservation, storage and transportation if the pharmaceutical warehouse management is ineffective. Risk of being fined if not meeting the requirements of the management agency.

6. Difficulty in preparing statistical reports

Monitoring and reporting on inventory statistics is often difficult due to fragmented data, a lot of paperwork, and time-consuming compilation and arrangement. Difficulty in making business decisions based on inventory data.

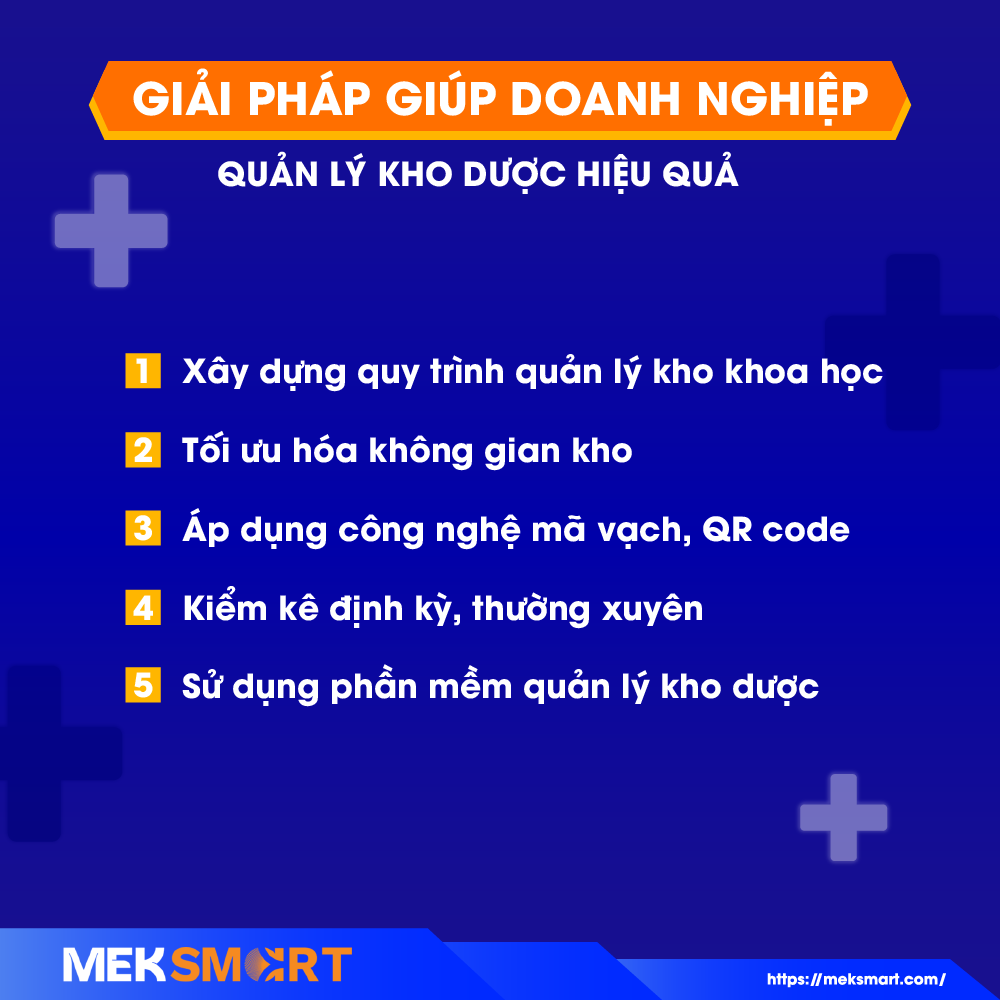

Some solutions to help businesses manage pharmaceutical warehouses effectively

Solutions to help businesses manage pharmaceutical warehouses effectively

1. Build a scientific warehouse management process

- Establish a clear and standardized process for importing - exporting, inventorying and preserving goods.

- Assign specific responsibilities to each employee, each department, and area.

- Train and improve employees' understanding of warehouse management processes and industry regulations.

2. Optimize warehouse space

- Arrange goods according to the FIFO (First In, First Out) or FEFO (First Expired, First Out) principle.

- Use shelves, racks and specialized storage equipment.

- Ensure the warehouse is always clean, dry and airy.

3. Apply barcode and QR code technology

- Help inventory goods quickly and accurately.

- Track the origin and movement history of each product.

4. Periodic and regular inventory

- Conduct periodic inventory to detect and promptly handle errors.

- Use warehouse management software to support the inventory process.

5. Use pharmaceutical warehouse management software

- Automate import - export, inventory and reporting processes.

- Manage product information, expiry date, production batch and storage location of each product.

- Enhance inventory control, minimize errors and losses.

Contact us for free consultation on effective and smart pharmaceutical warehouse management solutions, improving the competitiveness and position of businesses in the market!