MEKSMART

GENERAL NEWS

Author: Meker M

Update: 14/12/2022

Warehouses and Types of Warehouses in the Supply Chain

1. What is a warehouse?

Warehouse is a type of logistics facility that stores, preserves and prepares goods in order to provide goods to customers with the highest service level and lowest cost.

2. Why have a warehouse?

Supply and demand are more consistent (storage)

- Demand and supply are not always in sync

- Store products to respond to shortages or unexpected demand

Create acquisition opportunities (traffic)

- Large shipments have lower costs per shipping unit

- Discount opportunities when buying in bulk

3. Main Operation Functions

3.1 Receive

- Destination planning

- Manage unloading place

- Receipt of raw materials

- Unloading and staging

- Check for damage, classification, lack of goods, ..

3.2 Put-Away

- Material handling

- Verify storage location

- Move materials in

- Storage area

- Level of profile and position

- Set the location for the goods

3.3 Store

- Material storage

- Consume space

- Take more time

- Multiple storage forms: pallet, case, each

3.4 Pick

- Move items from storage to order

- Verify existing inventory

- Create shipping documents

- Includes move, search and extract

3.5 Check - Pack ‐ Ship

- Check order completion

- Document Confirmation

- Placed in the package(s)

- Collect orders

- Schedule a delivery

- Loading goods into the car

3.6 VAS

- Labeling, special packaging, small assembly, installation, re-pricing, and more.

3.7 Return

- Product flow processing returns with multiple reasons (damage, expiration, return, etc.)

- Can run 5% (retail) and up to 30% (e-commerce) in volume

- Steps may include inspection, repair, reuse, refurbishment, recycling and/or disposal

4. Functions of the warehouse

Consolidation: When a consignment/material is not in sufficient quantity, the Consolidator will gather, arrange and rationally arrange the odd shipment into consignments of sufficient quantity to use the full container shipping method. When goods/materials are received from many small sources, the warehouse acting as a gathering point for such large shipments will have the advantage of scale when transported to the factory or market by other means. transportation facility.

Commodity coordination: In order to well meet the customer's orders of many diverse items, the warehouse manager is responsible for separating large shipments, coordinating and combining different types of goods into a complete order, Make sure the goods are ready for sale.

Securing and storing goods: Ensuring goods are intact in terms of quantity and quality throughout the operation process, making the most of the warehouse area and capacity, taking care of goods in the warehouse.

5. Types of warehouses

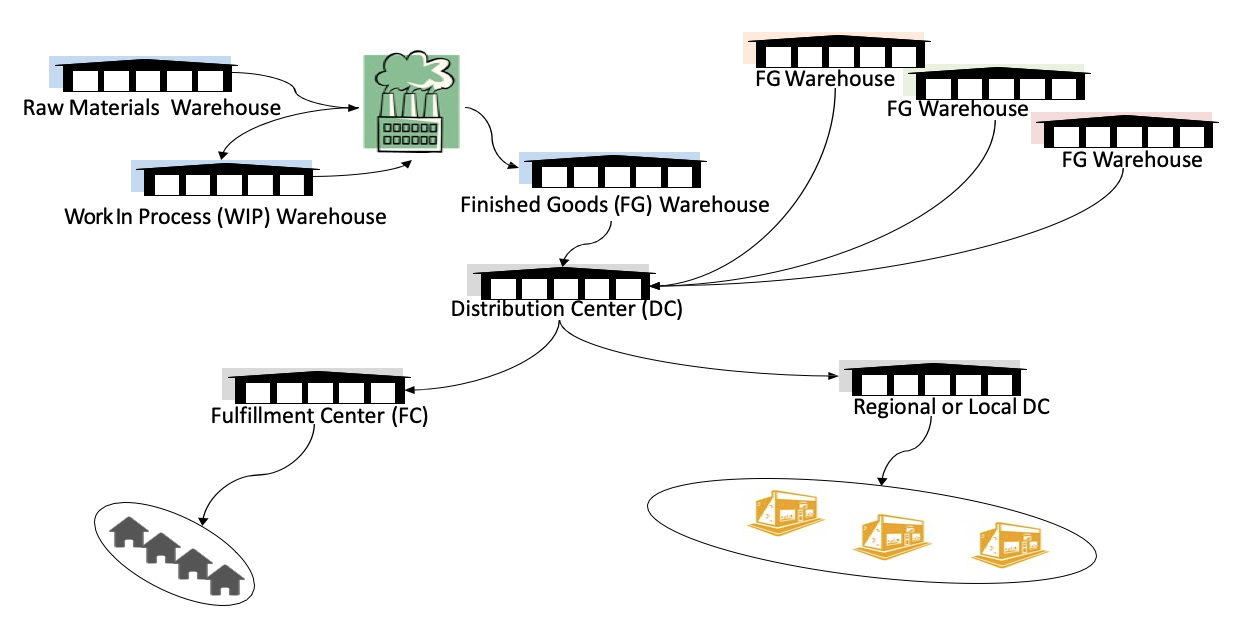

In today's enterprise supply chain, there are many types of warehouses. Depending on the purpose of use, specificity, services provided,... Here are some common types of warehouses in businesses:

General characteristics of some types of warehouse:

- Raw Material Storage: near the source of goods or production points.

- WIP Warehouses: partially completed parts and components.

- Finished Goods warehousing: located near the production area.

- Local Warehouses: close to the customer's location for timely delivery and feedback.

- Fulfillment Centers: holding products and sending small orders to individual consumers (multiple or individual) – mainly for e-commerce

- Distribution Centers: integrate and consolidate products from multiple sources for shipments to the same destination or customer.

- Mixing Centers: Receive materials from multiple sources for cross-docking and transport of mixed materials.

5.1 Bonded warehouse

Bonded warehouse: A warehouse and yard area established in the territory of Vietnam. Separation from the surrounding area to temporarily store, preserve or perform some services for goods imported from abroad or brought into the warehouse from within the country according to the bonded warehouse lease contract signed between the bonded warehouse owner and shippers.

5.2 Automated Warehouse

Automated Warehouses: Automated warehouses are highly efficient, fast and flexible. Automated warehouses use order tracking software to receive, store, and move goods. Automated warehouses also use modern equipment such as forklifts, racks and pallets to move goods quickly in the warehouse. With the right wholesale distribution software, there is less human error in management and the ability to receive and ship goods more efficiently.

5.3 Kho hàng ôn hòa (kho hàng lạnh)

Kho ôn hòa: Duy trì nhiệt độ trong một phạm vi cài đặt để chất lượng hàng hóa vẫn còn nguyên vẹn. Các nhà kho này sử dụng các thiết bị làm mát hoặc sưởi ấm được đặt ở vị trí chiến lược và yêu cầu có thể thay đổi tùy thuộc vào các yếu tố như mùa và đặc tính của sản phẩm được lưu trữ.

5.4 Distribution warehouse

Distribution warehouse: Distribution warehouses (distribution centers) are used to store and sell large quantities of goods. Typically, distribution centers stock goods from multiple manufacturers and in turn sell them to retailers.

Goods are usually stored for a short period of time; in some cases just a few days at a time. The distribution center is an important part of the supply chain, so it is important to set it up correctly. With a well-functioning supply chain, businesses will be able to better serve a large number of customers.

5.5 E-commerce warehouse

An e-commerce warehouse, also known as an order fulfillment center: is the warehouse of a company providing 3rd party logistics services (3PL). Place for order processing, picking, packaging and shipping for e-commerce partners.

Fulfillment centers are used by many e-commerce companies today to outsource the storage and shipping of their goods.

In this model, the merchant ships the goods to the fulfillment center, and when an order is placed, the fulfillment center delivers the order. This eliminates the growing need for e-commerce retailers to maintain their own inventory.

Conclude

Currently, Meksmart has provided a management & operation solution (Mek Warehouse Management System) for most warehouses and distribution centers. MEK- WMS is an ideal choice for logistics management businesses, the system has been used for fast moving consumer goods (FMCG), food-beverage (F&B), and pharmaceutical (Pharmacy) industries. , chemicals (chemicals), electronics (Electronic), textiles (Garment),...