MEKSMART

GENERAL NEWS

Author: Meker Meksmart

Update: 23/07/2025

OPTIMIZE STORAGE SPACE IN HOUSEHOLD WAREHOUSE MANAGEMENT

Household goods warehouse management is not only a problem of area but also a problem of efficiency and operating costs. With the characteristics of goods being diverse in size, shape and life cycle, optimizing storage space plays a key role in minimizing processing time, storage and transportation costs. However, in reality, no matter how scientifically arranged the warehouse is, chaos can easily occur without a strict management process and effective supporting technology.

In the following article, MEKSMART will share 5 practical tips to help businesses optimize their household goods warehouse system in a systematic and sustainable way.

1. Why do businesses need to optimize storage space in household goods warehouse management?

Household goods are diverse in size, shape and durability, from small fragile items to bulky equipment such as furniture and electrical appliances. If storage space is not optimized, businesses can easily waste space, increase operating costs and reduce order processing efficiency.

Optimizing space not only helps manage goods scientifically and easily, but also contributes to maintaining suitable storage conditions, limiting damage, especially for sensitive items. Applying technology and arranging things reasonably in the warehouse also helps businesses increase the speed of goods circulation, reduce inventory costs and improve the delivery experience for customers.

Optimizing space helps maintain suitable storage conditions, limiting damage

2. Effective household goods warehouse management process: Optimize operations and storage space

With the characteristics of diverse, fragile and unevenly sized goods, household goods warehouse management requires a methodical, scientific process and the application of technology to ensure operational efficiency.

Step 1: Warehouse entry:

- Receive and check goods: Check quantity, quality, packaging condition before importing.

- Create import form using software: Use warehouse management system (WMS) to accurately record goods information.

- Assign barcodes - standardize data: Assign barcodes or RFID to help track products easily and retrieve quickly.

Step 2: Warehousing: Optimize space and storage

- Arrange according to warehouse diagram: Classify and locate products in clear areas, making the most of space.

- Apply FIFO/LIFO flexibly: Ensure goods are circulated in the correct order, reducing backlog and loss.

- Periodic inspection: Monitor quality and expiry date to promptly handle risks.

Step 3: Warehouse exit:

- Handle export requests: Prepare orders quickly, with correct type and quantity.

- Automatic inventory creation and update: Data synchronization helps track accurate quantities.

- Traceability: Supports supply chain transparency, enhances brand reputation.

Step 4: Periodic inventory:

- Inventory combining manual and technology: Reduce data errors, save time.

- Discrepancy reporting - cause handling: Analysis to provide effective adjustment directions.

- Inventory data analysis: As a basis for making decisions for import - export plans and optimizing warehouse space.

3. 5 Tips to optimize storage space in household goods warehouses

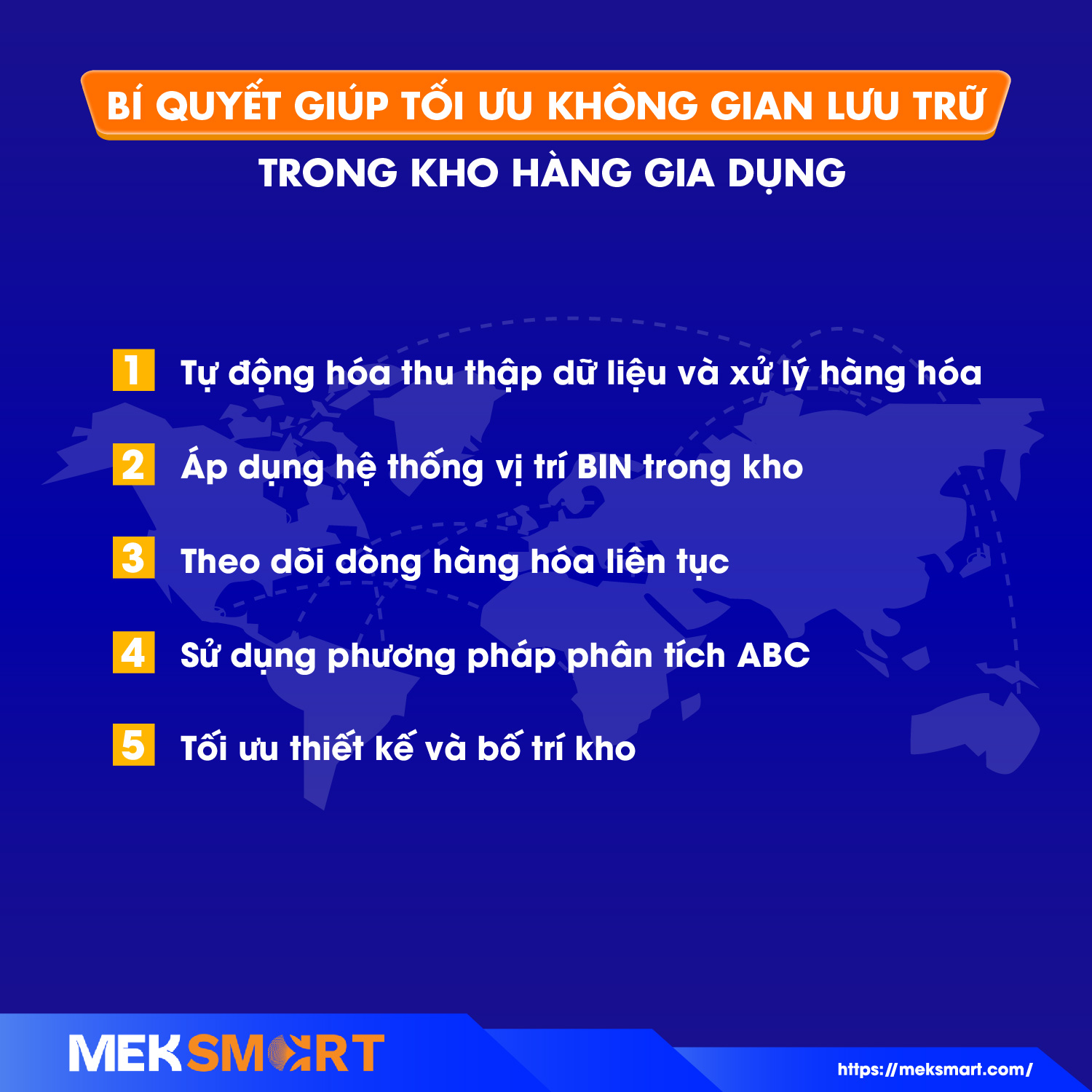

Optimizing storage capacity not only helps save space, but also improves operational efficiency and minimizes warehouse costs. Here are 5 tips to help home goods businesses make the most of their warehouse space:

- Automate data collection and goods processing: Applying technology such as barcodes, RFID, and WMS software helps reduce errors and increase accuracy when importing - exporting - storing goods, especially for fragile and diverse products.

- Apply the BIN location system in the warehouse: Managing storage locations according to the BIN system (row - column - shelf) helps employees easily locate goods, increase order processing speed and limit losses due to location errors.

- Continuously track the flow of goods: Analyzing the flow of goods helps businesses adjust import plans, reduce unnecessary inventory and prioritize space for best-selling products.

- Use the ABC analysis method: Classify inventory by value (A - B - C) to help determine storage priorities, focus space and resources on product groups that generate the highest revenue.

- Optimize warehouse design and layout: Take advantage of vertical space, arrange shelves scientifically, avoid random stacking of goods to increase storage capacity without expanding the area, while improving the working efficiency of warehouse staff.

Combining the above tips, combined with a modern warehouse management system, will help household goods businesses optimize storage space in a sustainable, professional and cost-saving way.

Secrets to optimize storage space in household goods warehouses

4. Meksmart - Optimal household goods warehouse management solution for businesses.

With the MEKWMS solution integrated with AI and IoT, Meksmart helps household goods businesses strictly control all warehouse activities - from import, storage, export to inventory.

- Standardize storage process: Automatically assign barcodes, classify and locate products clearly according to the warehouse diagram.

- Optimize space and inventory: Apply scientific storage principles (FIFO/LIFO), combine ABC analysis to maximize storage space.

- Control goods quality: Warning system for fragile goods, near expiration or stored for too long, minimizing damage and loss.

- Integrate smart data: Synchronize with sales and transportation systems, ensuring smooth, accurate and timely information flow.

- Real-time operation reports: Provide detailed inventory data, support quick and effective decision making.

Meksmart helps household goods businesses closely control all warehouse activities

In the context of an increasingly competitive market, scientific and accurate management of household goods warehouses is the key to helping businesses optimize costs, increase efficiency and improve customer experience. Applying MEKWMS not only helps automate the import - export - inventory process, but also provides the ability to monitor data in real time and support quick and accurate decision making.

Contact Meksmart now for advice and experience a flexible, modern and scalable household goods warehouse management system.